Zing™ HUMS On-Board VXP

Zing™ HUMS On-Board VXP

High-Performance on-Board Track, Balance & Vibration Monitoring Systems for helicopters and fixed-wing aircraft using an “Optical Tracker” and “Advanced Smart Chart” Technology, for quick Track & Balance data collection and integrated Track & Balance solutions, saving valuable flight time or some single test flights. Calculated adjustments respect current rotor settings and given limits.

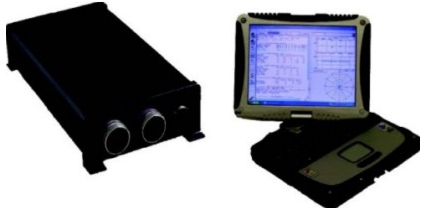

On-Board VXP

The Honeywell Chadwick Helmuth’s VXP Health Monitoring System represents more than 50 years of experience and is one of the latest in the Honeywell Health & Usage Monitoring Systems (HUMS) product lines. It is the most advanced Aviation Vibration Health Monitoring System available on the market and represents a merging of On-Board System and Ground-Based Technologies.

Honeywell Chadwick Helmuth’s VXP is fully certified and available via STC’s and PMA’s and not only meets the current regulatory requirements but also has provisions to support future HUMS functions. In addition, the system enhances safety through early detection of mechanical faults preventing catastrophic failures. The VXP provides a dramatic reduction in maintenance man-hours, maximum flexibility, and the latest advancements in technology, system growth, low costs, proven reliability and existing Honeywell world-renowned customer support.

Honeywell Chadwick Helmuth On-Board VXP Benefits/Features :

![]() Light weight and quick download (30 seconds)

Light weight and quick download (30 seconds)

![]() On-Board vibration diagnostics to provide actionable maintenance information at the aircraft.

On-Board vibration diagnostics to provide actionable maintenance information at the aircraft.

![]() Continuous monitoring without human intervention versus “snap shot” data collection

Continuous monitoring without human intervention versus “snap shot” data collection

![]() Integrated Rotor Track and Balance Data to provide the most advanced T&B solution with expanded Smart Chart technology Comprehensive ground support software tools available for flight crews, maintainers, and engineers with capabilities to interface with operators’ maintenance system

Integrated Rotor Track and Balance Data to provide the most advanced T&B solution with expanded Smart Chart technology Comprehensive ground support software tools available for flight crews, maintainers, and engineers with capabilities to interface with operators’ maintenance system

Zing™ HUMS On-Board VXP Technical Specifications |

||||

Acquisition Unit Balance Measurements |

Interfaces |

|||

| Amplitude Accuracy | +/- 2% | • Magnetic Pickup/Photocell, 4 ea / Tachometer, 4 ea | ||

| Phase Resolution | 1 degree | • Photoprobe (high speed), 2 ea / Velocimeter, 16 ea | ||

| Frequency Range | 180 to 60,000 RPM | • Accelerometer, 26 ea / Accelerometer (charge), 6 ea | ||

| Harmonics | 1 to 5 | • Discrete Signal I/O, 6 ea / Strobex, 1 ea / FasTrak™, 1 ea | ||

| Simultaneous Channels | 4 vib., 1 azimuth, 1 FasTrak™ | • Serial Interface, 3 ea / Cockpit Control Unit, 1 ea• PCMCIA Type 1, 2 Card Slot / USB | ||

| Vector Operations | A, (A+B)/2, (A-B)/2 | • Internal aircraft databus interface slot | ||

Track Measurements with FasTrak™ |

Physical |

|||

| Track Height Accuracy | +/- 2 mm | Dimensions | 7.1 W x 3.0 H x 12.2 D (inches), 180 W x 76 H x 304 D (mm) | |

| Lead Lag Accuracy | +/- 0.5 mm | Weight | 6.2 lbs., 2.82 kg | |

Spectrum |

Power Requirement | 18 to 32 VDC | ||

| Frequency Ranges | 0-20 Hz to 0-75 kHz | Operating Temperature Range | -30 to +60°C | |

| Frequency Resolution | 400 to 51,200 lines | Storage Temperature Range | -55 to +85°C Carry-On | |

| Zoom | Yes |

VXP Display Unit |

||

| Window Types | Flat-top, Hanning, Kaiser-Bessel, Uniform | Dimensions | 10.7 W x 1.9 H x 8.5 D (inches), 272 W x 48 H x 216 D (mm) | |

| Simultaneous Channels | 4 vib., 1 azimuth | Weight | 4.5 lbs., 2.0 kg | |

| Dynamic Range | >90 dB | Power Requirement | Intel Centrino Duo, 1.06 GHz | |

| Averaging | Linear, Peak | Display | Color Active Matrix, Sunlight readable tablet PC | |

Filters |

Pointing Devices | Touch pad and touch screen | ||

| 1 to 8 simultaneous filters (any combination of broadband and tracking filters allowed) | Disk Drive Capacity | 80 GB | ||

Processing |

Memory | 512 MB SDRAM | ||

| 32 Bit Microprocessor (CPU), Digital Signal Processor (DSP), RISC based Time Processor Unit (TPU) | Interfaces | RS-232, USB, PCMCIA Type 1, 2 | ||

| Honeywell reserves the right to change specifications without notice. Centrino is trademark of the Intel Corp., Windows is a trademark of Microsoft. | ||||

Enhanced VXP (EVXP)

As the newest member of the Honeywell Chadwick Helmuth Health and Usage Monitoring System (HUMS) family, the Enhanced VXP (EVXP) provides the features and functions to meet increasing regulatory and customer-driven requirements for an aircraft health monitoring system.

Honeywell Chadwick Helmuth’s EVXP System monitors aircraft health, operational, and usage parameters. In order to be able to meet all of the basic maintenance requirements, the system performs data management, enhanced vibration diagnostics for detecting issues, event or exceedance detection, main rotor track and balance, tail rotor balancing, operations usage recording, and system functions

Honeywell Chadwick Helmuth EVXP Benefits/Features :

![]() Simultaneously collecting data from up to four vibration, azimuth and tracking inputs

Simultaneously collecting data from up to four vibration, azimuth and tracking inputs

![]() Collecting both vibration and Rotor Track and Balance flight regime data in any order, thereby providing flexibility during dedicated flight tests and eliminating the need to restart tests

Collecting both vibration and Rotor Track and Balance flight regime data in any order, thereby providing flexibility during dedicated flight tests and eliminating the need to restart tests

![]() Providing immediate feedback of vibration exceedances via the DU, thereby eliminating the need to review the data post-flight using the ground station software. Comprehensive ground support software tools available for flight crews, maintainers, and engineers with capabilities to interface with operators’ maintenance system

Providing immediate feedback of vibration exceedances via the DU, thereby eliminating the need to review the data post-flight using the ground station software. Comprehensive ground support software tools available for flight crews, maintainers, and engineers with capabilities to interface with operators’ maintenance system

For Additional information feel free to contact us

Vibration Monitoring System (VMS II)

Slim, lightweight monitor is mounted out of sight in wardrobe for easy access to propeller balance data. The VMS II:

![]() Low-Investment on-Board Track, Balance & Vibration Analysis System for helicopters and fixed-wing aircraft using an “Optical Tracker” and “Smart Chart” Technology, for quick Track & Balance data collection and integrated Track & Balance solutions, saving valuable flight time or some single test flights.

Low-Investment on-Board Track, Balance & Vibration Analysis System for helicopters and fixed-wing aircraft using an “Optical Tracker” and “Smart Chart” Technology, for quick Track & Balance data collection and integrated Track & Balance solutions, saving valuable flight time or some single test flights.

![]() Permanent on-board system.

Permanent on-board system.

![]() Installs easily.

Installs easily.

![]() Quickly connects to a desktop or laptop PC for simple operation.

Quickly connects to a desktop or laptop PC for simple operation.

![]() Automatically collects propeller vibration data during revenue flights.

Automatically collects propeller vibration data during revenue flights.

![]() Fine-tunes propeller balance for lower aircraft vibration.

Fine-tunes propeller balance for lower aircraft vibration.

![]() Calculated adjustments respect current rotor settings and given limits.

Calculated adjustments respect current rotor settings and given limits.

![]() Certified (STC’d) for DeHavilland Dash-8 and for Eurocopter EC135.

Certified (STC’d) for DeHavilland Dash-8 and for Eurocopter EC135.

![]() Meets requirements for JAR OPS-3 and VHM (CAP-753).

Meets requirements for JAR OPS-3 and VHM (CAP-753).

![]() Reduces operating costs.

Reduces operating costs.

For more Information about Honeywell Zing HUMS, feel free to contact us

VMSII Characteristics |

|||

Signal interfaces & devices for data download: |

|||

| Portable Computer | serial, RS-232, Windows 95 | ||

| Printer | serial, RS-232 | ||

| Memory card | PCMCIA Type II, static RAM (SRAM) | ||

| Vibration signal inputs: | 2 velocimeters for each aircraft | ||

| Azimuth signal inputs: | 2 magnetic pickups (tachs) | ||

| Channels: | 2 parallel processing channels | ||

| Processor Unit: | height | 1.2 inches | 3 cm |

| width | 5.3 inches | 13.5 cm | |

| depth | 8.0 inches | 20.3 cm | |

| weight | 1.5 pounds | 0.7 kilos | |

Visual Blade Tracker “Strobex 135M-12” P/N 8620

![]() It requires “Tip Targets” on the blade tip which are usually part of the Application Kit for V2K(+), Carry-On VXP and 8500C(+).

It requires “Tip Targets” on the blade tip which are usually part of the Application Kit for V2K(+), Carry-On VXP and 8500C(+).

![]() Observed Track & Lead/Lag data are either recorded on a tracking record sheet or entered in the 8500C(+) “Smart Chart” to be respected in the calculated Track & Balance adjustments.

Observed Track & Lead/Lag data are either recorded on a tracking record sheet or entered in the 8500C(+) “Smart Chart” to be respected in the calculated Track & Balance adjustments.

Optical Blade Tracker “FasTrak” P/N 11800-3

![]() When used with Carry-On VXP the Track & Lead/Lag data are collected simultaneously while measuring the dynamic balance.

When used with Carry-On VXP the Track & Lead/Lag data are collected simultaneously while measuring the dynamic balance.

![]() For use at night, a Retro Reflective self-adhesive tape is used at the trailing edge of the rotor blades to reflect the emitted IR light of the IR LCD ring below the cover glass.

For use at night, a Retro Reflective self-adhesive tape is used at the trailing edge of the rotor blades to reflect the emitted IR light of the IR LCD ring below the cover glass.

Portable Printer “DPU-414-M”

![]() This line printer makes it comfortable for the user, to get printouts at the aircraft, without the need of a PC Printer in an office.

This line printer makes it comfortable for the user, to get printouts at the aircraft, without the need of a PC Printer in an office.

![]() Its rechargeable battery allows printing even without supply power from the aircraft. The rechargeable battery is charged via the Acquisition Unit of the Carry-On VXP.

Its rechargeable battery allows printing even without supply power from the aircraft. The rechargeable battery is charged via the Acquisition Unit of the Carry-On VXP.

Vibration Sensors

![]() High Temp. Accelerometer used for vibration test and analysis on turbine engines.

High Temp. Accelerometer used for vibration test and analysis on turbine engines.

![]() Accelerometer 4177B, P/N 4109 used for the legacy VIBREX System with Balancer 177M-6.

Accelerometer 4177B, P/N 4109 used for the legacy VIBREX System with Balancer 177M-6.

Azimuth Sensors

![]() Photo Probe , P/N 10200-1 typically used as RPM and azimuth reference for dynamic balance measurement of tail rotors, drive shafts and blowers, with 8500C(+) and Carry-On VXP.

Photo Probe , P/N 10200-1 typically used as RPM and azimuth reference for dynamic balance measurement of tail rotors, drive shafts and blowers, with 8500C(+) and Carry-On VXP.

![]() Photo Probe , P/N 12900 typically used as RPM and azimuth reference for dynamic balance measurement of tail rotors, drive shafts and blowers, with V2K(+)

Photo Probe , P/N 12900 typically used as RPM and azimuth reference for dynamic balance measurement of tail rotors, drive shafts and blowers, with V2K(+)

Sensor Cables

![]() Magnetic Pickup Cables, P/N 10808-X available in different lengths, used for V2K(+), Carry-On VXP and 8500C(+).

Magnetic Pickup Cables, P/N 10808-X available in different lengths, used for V2K(+), Carry-On VXP and 8500C(+).

![]() Photo Probe Cables, P/N 10185-X available in different lengths, used for V2K(+), Carry-On VXP and 8500C(+).

Photo Probe Cables, P/N 10185-X available in different lengths, used for V2K(+), Carry-On VXP and 8500C(+).

Azimuth Reflectors and Tip Targets

![]() The Reflector Set P/N 3300 is applicable as Azimuth Reflectors for the Photo Probe P/N 10200-1 as well as for the Tip Targets 3428-2/-4.

The Reflector Set P/N 3300 is applicable as Azimuth Reflectors for the Photo Probe P/N 10200-1 as well as for the Tip Targets 3428-2/-4.

![]() The full selection of retro reflective material for use as Tip Targets with out bracket or as spare for Tip Targets is shown and described under “Details”.

The full selection of retro reflective material for use as Tip Targets with out bracket or as spare for Tip Targets is shown and described under “Details”.

Basic Sensor Brackets

![]() The Photocell Bracket P/N 10423(-1) is used for installation of the Photo Probe , P/N 12900.

The Photocell Bracket P/N 10423(-1) is used for installation of the Photo Probe , P/N 12900.

![]() Aircraft specific Brackets for Accelerometer 4177B and Velocimeter 7310 are offered as part of Application Kits, if needed.

Aircraft specific Brackets for Accelerometer 4177B and Velocimeter 7310 are offered as part of Application Kits, if needed.

Application Kits

![]() The required Application Accessory is quoted specifically for the various “Portable Systems” and aircraft/engine type.

The required Application Accessory is quoted specifically for the various “Portable Systems” and aircraft/engine type.

Brackets and Interrupters

![]() Interrupters are aircraft specific parts made of magnetic Stainless Steel which generates an RPM and azimuth reference when passing the Magnetic Pickup.

Interrupters are aircraft specific parts made of magnetic Stainless Steel which generates an RPM and azimuth reference when passing the Magnetic Pickup.

![]() Brackets and Interrupters are available for many helicopter and fixed-wing aircrafts, as part of the Application Kit for “Zing® Test” Systems.

Brackets and Interrupters are available for many helicopter and fixed-wing aircrafts, as part of the Application Kit for “Zing® Test” Systems.

Adapter Cables

![]() Breakout Cables are used for aircrafts which have a partly or complete hardwiring for DC Supply power and sensors of the “Zing® Test” Systems.

Breakout Cables are used for aircrafts which have a partly or complete hardwiring for DC Supply power and sensors of the “Zing® Test” Systems.

Application Software

![]() The “Advanced Smart Charts” of the Carry-On VXP allow simple/quick data collection of Track & Balance of one or multiple regimes and calculate rotor adjustments for Track and/or Balance respecting current settings and rotor limits.

The “Advanced Smart Charts” of the Carry-On VXP allow simple/quick data collection of Track & Balance of one or multiple regimes and calculate rotor adjustments for Track and/or Balance respecting current settings and rotor limits.

![]() For 8500C(+) Chart Sets are provided in form of a 3.5” Floppy Disk, containing “Smart Charts” available for almost any helicopter and turboprop aircraft type as well as for some turbofan engines.

For 8500C(+) Chart Sets are provided in form of a 3.5” Floppy Disk, containing “Smart Charts” available for almost any helicopter and turboprop aircraft type as well as for some turbofan engines.

Precision Tab Tools (optional)

![]() Precision Tab Tools are available for many different helicopter types from Honeywell, supplied with calibration plates and instructions and partly with a specific carrying case.

Precision Tab Tools are available for many different helicopter types from Honeywell, supplied with calibration plates and instructions and partly with a specific carrying case.