Vibrex 2000 / 2000+

Vibrex 2000 / 2000+

Cost-effective balancer/analyzer with superior performance.

- Propeller balance

- Helicopter track & balance

- Vibration analysis

- Multiple channel input for multiple balance jobs

- Automatic weight sensitivity correction

- RS232 interface for connection to printer and/or PC

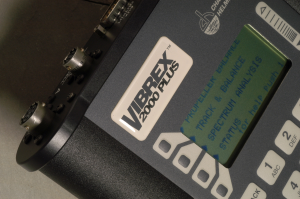

Vibrex™ 2000 and Vibrex™ 2000 Plus

Whether you have a fixed-wing aircraft, helicopter, turbine or reciprocating engine, there’s a Vibrex 2000(+) to meet your needs. The Vibrex 2000(+) is a vibration analysis and balancing tool that rapidly and accurately acquires and analyzes aircraft.The “Smart Balance Chart” calculates balance weights for Propellers and rotors for Propellers of any size and type with weight splitting and automatic sensitivity. Vibrex 2000(+) uses Stroboscope for visual rotor tracking & Lead/Lag Check.

The balancer/analyzer for fixed-wing or rotorcraft

The balancer/analyzer acquires accurate propeller and helicopter vibration readings. The Vibrex™ 2000(+) will balance propellers without the need of a chart or use the available Chadwick paper charts or factory charts, to balance your helicopter. Also capable of balancing shafts and blowers, the Vibrex™ 2000(+) is a complete balancing tool. As a spectrum analyzer, it provides the operator with an overview of rotor and drivetrain vibration.

2 models to fit your needs

Vibrex™ 2000

The basic Vibrex™ 2000 is applicable to aircraft and engines with component frequencies of 20,000 rpm or less and balance speeds below 10,000 rpm. For recipe powered aircraft, the Vibrex™ 2000 basic model is a sure fit.

Vibrex™ 2000 Plus

For applications where there is a need to perform higher frequency spectrum analysis, such as a turbine engine, the Vibrex™ 2000 Plus measures to 600,000 rpm. The Vibrex™ 2000 Plus model also adds a spectrum viewer for on-screen graphical display of spectral data. Both models provide easy-to-use features that assist the maintainer in decreasing maintenance time, lowering maintenance costs and increasing aircraft availability.

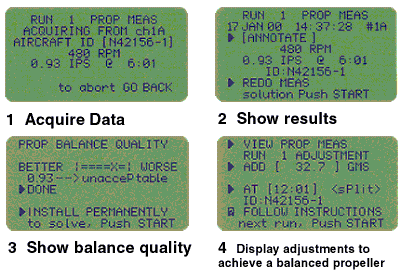

4 easy steps to FAA-approved prop balance

Easy to understand menus allow the user to initiate and complete up to 4 different balancing jobs at one time. The instrument will automatically correct for the propeller response to weight changes and this correction can be saved for future balancing exercises.

A “first round hit” solution means less vibration, even on the first adjustment. Two channels allow the user to measure the propeller and rear of the engine during balancing. All measurements, sensitivities, solutions, and annotations are stored in memory and can be reviewed on the instrument, printed on the optional portable thermal printer, or downloaded to a personal computer.

Customized Kits Available

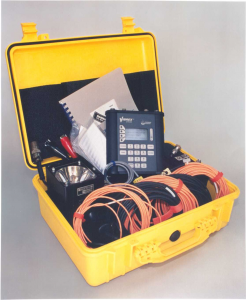

The Vibrex™ 2000 product line comes as a complete kit, with all the software, accessories, and instructions for your particular application in a rugged, portable carrying case. With over 45 years of experience on more that 300 different applications, Honeywell-Chadwick systems are proven and reliable.

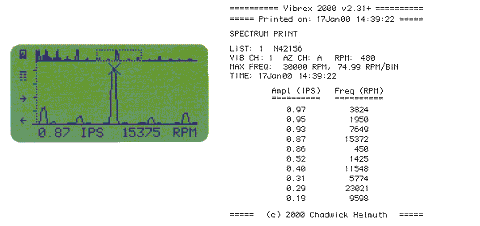

Pinpoint problem components Spectrum Analysis

Use the Vibrex™ 2000 spectrum feature to pinpoint problem components with ease. The “List Peaks” spectrum printout identifies the highest peaks quickly. Use the harmonic and order features to identify misalignment, mechanical looseness, or imbalance to guide your maintenance action.

An added feature of the Vibrex 2000 Plus model is a simple yet sophisticated spectrum viewer.

Vibrex 2000 / 2000+ Specifications |

|

Physical |

|

| Dimensions | 7.38″H x 7.25″W x 1.81″D (18.75 cm x 18.42 cm x 4.6 cm) |

| Weight | 3.5 lbs. (w/o batteries) (nominal) |

| Power requirement | 3-6.4 VDC 250mA |

Interfaces |

|

| Vibration sensor | 2 ea. Velocimeter (19 mV/IPS sensitivity) |

| Mag pickup / tach. | 2 ea. Pulse input, magnetic pickup or logic type |

| Accessory Power | 4 ea. D-Cell batteries. (Reverse polarity circuit protected and fused) |

| Portable Computer or Printer | 1 Serial, RS-232, 9600baud |

Balance Measurements |

|

| Phase accuracy | ± 5 Minutes or ± 2.5° |

| Balance frequency range | 240 to 10,000 RPM (Basic & French) (120 to 30,000 RPM (Plus)) |

| Phase resolution | 2 minutes or 1 degree |

Spectrum Analysis (Fmax, RPM) |

|

| Vibrex™ 2000 Basic | 1,250 – 20,000 |

| Vibrex™ 2000 (French) | 3,000 – 24,000 |

| Vibrex™ 2000 Plus | 1,200 – 600,000 |

| FFT resolution | 400 Lines |

Performance |

|

| Memory | 1MB |

| Accuracy (Basic & French) | ± 5% from 5 Hz to 333 Hz |

| Accuracy (Plus) | ± .5dB from 2 Hz to 500 Hz (± 1dB from 501 Hz to 10 Kz) |

| Spurious free dynamic range | >60 dB |

| Velocimeter input ranges | 0 to 304mV peak (16 ips) |

| (Vibrex 2000 Plus) | 0 to 380mV peak (20 ips) |

| Velocimeter input sensitivity | 19mV/IPS peak |

| Mag p/u, input frequency range | 100 – 50,000 RPM |

| Mag p/u RPM accuracy | 0.1% |

| Mag p/u, input voltage range | 0.5 to 12 Volts peak nominal (120 Volts peak maximum) |

Environmental |

|

| Temperature | 0°C to 50°C, or 32°F to 120°F |

| EMI susceptibility and radiated emissions standards | |

| Industrial Electronic Control Equipment Class | CE certified to: Standard EN50081-2Standard EN50082-2 |

Ground Software |

|

| Vibrex™ 2000 Download | Included with all models |

| Vibrex™ 2000 Plot | Included w/2000 Plus (Optional w/Basic and French models) |

Visual Blade Tracker “Strobex 135M-12” P/N 8620

![]() It requires “Tip Targets” on the blade tip which are usually part of the Application Kit for V2K(+), Carry-On VXP and 8500C(+).

It requires “Tip Targets” on the blade tip which are usually part of the Application Kit for V2K(+), Carry-On VXP and 8500C(+).

![]() Observed Track & Lead/Lag data are either recorded on a tracking record sheet or entered in the 8500C(+) “Smart Chart” to be respected in the calculated Track & Balance adjustments.

Observed Track & Lead/Lag data are either recorded on a tracking record sheet or entered in the 8500C(+) “Smart Chart” to be respected in the calculated Track & Balance adjustments.

Optical Blade Tracker “FasTrak” P/N 11800-3

![]() When used with Carry-On VXP the Track & Lead/Lag data are collected simultaneously while measuring the dynamic balance.

When used with Carry-On VXP the Track & Lead/Lag data are collected simultaneously while measuring the dynamic balance.

![]() For use at night, a Retro Reflective self-adhesive tape is used at the trailing edge of the rotor blades to reflect the emitted IR light of the IR LCD ring below the cover glass.

For use at night, a Retro Reflective self-adhesive tape is used at the trailing edge of the rotor blades to reflect the emitted IR light of the IR LCD ring below the cover glass.

Portable Printer “DPU-414-M”

![]() This line printer makes it comfortable for the user, to get printouts at the aircraft, without the need of a PC Printer in an office.

This line printer makes it comfortable for the user, to get printouts at the aircraft, without the need of a PC Printer in an office.

![]() Its rechargeable battery allows printing even without supply power from the aircraft. The rechargeable battery is charged via the Acquisition Unit of the Carry-On VXP.

Its rechargeable battery allows printing even without supply power from the aircraft. The rechargeable battery is charged via the Acquisition Unit of the Carry-On VXP.

Vibration Sensors

![]() High Temp. Accelerometer used for vibration test and analysis on turbine engines.

High Temp. Accelerometer used for vibration test and analysis on turbine engines.

![]() Accelerometer 4177B, P/N 4109 used for the legacy VIBREX System with Balancer 177M-6.

Accelerometer 4177B, P/N 4109 used for the legacy VIBREX System with Balancer 177M-6.

Azimuth Sensors

![]() Photo Probe , P/N 10200-1 typically used as RPM and azimuth reference for dynamic balance measurement of tail rotors, drive shafts and blowers, with 8500C(+) and Carry-On VXP.

Photo Probe , P/N 10200-1 typically used as RPM and azimuth reference for dynamic balance measurement of tail rotors, drive shafts and blowers, with 8500C(+) and Carry-On VXP.

![]() Photo Probe , P/N 12900 typically used as RPM and azimuth reference for dynamic balance measurement of tail rotors, drive shafts and blowers, with V2K(+)

Photo Probe , P/N 12900 typically used as RPM and azimuth reference for dynamic balance measurement of tail rotors, drive shafts and blowers, with V2K(+)

Sensor Cables

![]() Magnetic Pickup Cables, P/N 10808-X available in different lengths, used for V2K(+), Carry-On VXP and 8500C(+).

Magnetic Pickup Cables, P/N 10808-X available in different lengths, used for V2K(+), Carry-On VXP and 8500C(+).

![]() Photo Probe Cables, P/N 10185-X available in different lengths, used for V2K(+), Carry-On VXP and 8500C(+).

Photo Probe Cables, P/N 10185-X available in different lengths, used for V2K(+), Carry-On VXP and 8500C(+).

Azimuth Reflectors and Tip Targets

![]() The Reflector Set P/N 3300 is applicable as Azimuth Reflectors for the Photo Probe P/N 10200-1 as well as for the Tip Targets 3428-2/-4.

The Reflector Set P/N 3300 is applicable as Azimuth Reflectors for the Photo Probe P/N 10200-1 as well as for the Tip Targets 3428-2/-4.

![]() The full selection of retro reflective material for use as Tip Targets with out bracket or as spare for Tip Targets is shown and described under “Details”.

The full selection of retro reflective material for use as Tip Targets with out bracket or as spare for Tip Targets is shown and described under “Details”.

Basic Sensor Brackets

![]() The Photocell Bracket P/N 10423(-1) is used for installation of the Photo Probe , P/N 12900.

The Photocell Bracket P/N 10423(-1) is used for installation of the Photo Probe , P/N 12900.

![]() Aircraft specific Brackets for Accelerometer 4177B and Velocimeter 7310 are offered as part of Application Kits, if needed.

Aircraft specific Brackets for Accelerometer 4177B and Velocimeter 7310 are offered as part of Application Kits, if needed.

Application Kits

![]() The required Application Accessory is quoted specifically for the various “Portable Systems” and aircraft/engine type.

The required Application Accessory is quoted specifically for the various “Portable Systems” and aircraft/engine type.

Brackets and Interrupters

![]() Interrupters are aircraft specific parts made of magnetic Stainless Steel which generates an RPM and azimuth reference when passing the Magnetic Pickup.

Interrupters are aircraft specific parts made of magnetic Stainless Steel which generates an RPM and azimuth reference when passing the Magnetic Pickup.

![]() Brackets and Interrupters are available for many helicopter and fixed-wing aircrafts, as part of the Application Kit for “Zing® Test” Systems.

Brackets and Interrupters are available for many helicopter and fixed-wing aircrafts, as part of the Application Kit for “Zing® Test” Systems.

Adapter Cables

![]() Breakout Cables are used for aircrafts which have a partly or complete hardwiring for DC Supply power and sensors of the “Zing® Test” Systems.

Breakout Cables are used for aircrafts which have a partly or complete hardwiring for DC Supply power and sensors of the “Zing® Test” Systems.

Application Software

![]() The “Advanced Smart Charts” of the Carry-On VXP allow simple/quick data collection of Track & Balance of one or multiple regimes and calculate rotor adjustments for Track and/or Balance respecting current settings and rotor limits.

The “Advanced Smart Charts” of the Carry-On VXP allow simple/quick data collection of Track & Balance of one or multiple regimes and calculate rotor adjustments for Track and/or Balance respecting current settings and rotor limits.

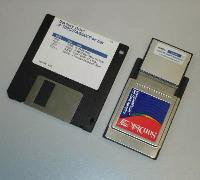

![]() For 8500C(+) Chart Sets are provided in form of a 3.5” Floppy Disk, containing “Smart Charts” available for almost any helicopter and turboprop aircraft type as well as for some turbofan engines.

For 8500C(+) Chart Sets are provided in form of a 3.5” Floppy Disk, containing “Smart Charts” available for almost any helicopter and turboprop aircraft type as well as for some turbofan engines.

Precision Tab Tools (optional)

![]() Precision Tab Tools are available for many different helicopter types from Honeywell, supplied with calibration plates and instructions and partly with a specific carrying case.

Precision Tab Tools are available for many different helicopter types from Honeywell, supplied with calibration plates and instructions and partly with a specific carrying case.